Creating a river table transforms ordinary wood into a stunning centrepiece, but What brand of epoxy is best for a river table project? This question puzzles many woodworkers in Bristol, Somerset, and across the South West. The right epoxy ensures crystal-clear pours up to 2-3 inches deep without bubbles, yellowing, or cracking.

As Jamie Simmonds, a master carpenter from Bristol specialising in wood and resin furniture, I’ve crafted countless river tables for clients in Cornwall, Dorset, and Wiltshire. From live edge walnut slabs to resin river breakfast bars, choosing the best epoxy brand makes all the difference. In this comprehensive guide, we’ll explore top brands, key properties, and practical tips tailored to UK climates where humidity in Gloucester or Plymouth can challenge pours.

Whether you’re a homeowner in Cheltenham planning a DIY dining table or a maker in Exeter building bespoke pieces, understanding what brand of epoxy is best for a river table project prevents costly mistakes. We’ll cover viscosities, pot lives, UV resistance, and real-world tests from my workshop experience.

Understanding What Brand of Epoxy is Best for a River Table Project

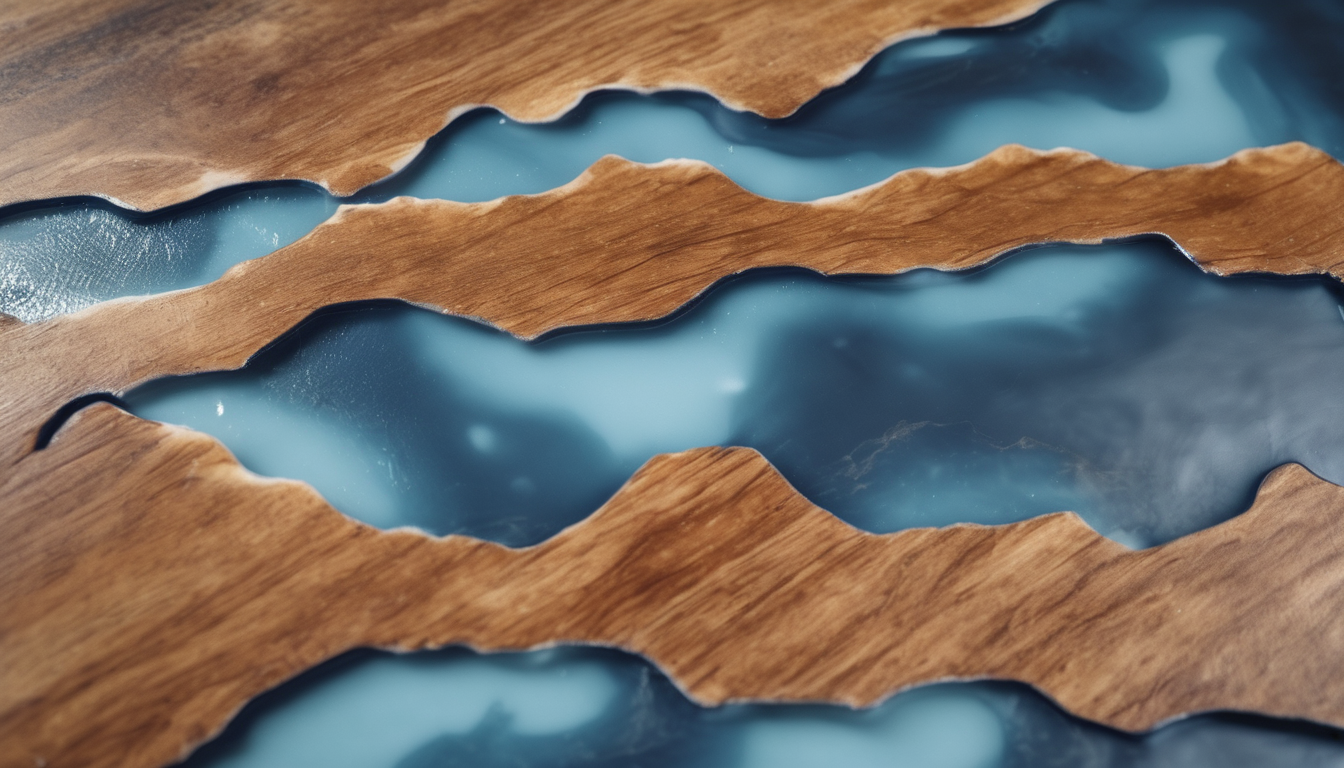

River tables feature a “river” of clear epoxy flowing between wood slabs, mimicking water. What brand of epoxy is best for a river table project? It must handle deep pours of 2-3 inches (50-75mm) in one go to avoid cold joints or weak layers[1][3].

In Bristol’s damp climate, epoxy needs low viscosity for self-levelling, long pot life over 400 minutes, and UV blockers to prevent yellowing from South West sunlight. High exothermic reactions cause heat and cracks, so low-heat formulas excel[1].

From my experience restoring period homes in Gloucestershire, the best brands prioritise clarity and bubble release. Poor choices yellow within months, ruining heirloom pieces for families in Swindon or Bournemouth.

Why Epoxy Matters More Than Wood in River Tables

Wood like oak or walnut from local Dorset suppliers is forgiving, but epoxy demands precision. The wrong brand leads to hazy rivers or delamination. Top picks like CHILL ICE shine here[1].

River tables demand casting epoxies, not tabletop coatings. Casting resins cure slowly for deep masses, unlike fast bar top formulas that overheat[4].

<h2 id="key-factors-to-consider-when-answering-what-brand-of-epoxy-is-best-for-a-river-table-project”>Key Factors to Consider When Answering What Brand of Epoxy is Best for a River Table Project

When deciding what brand of epoxy is best for a river table project, evaluate viscosity, pot life, depth per pour, and clarity. Low viscosity (water-like) wets wood fully without air pockets[1].

Pot life over 400 minutes allows mixing 20-60L for large Somerset kitchen islands. UV stability fights yellowing; blush resistance handles humid Cornish air[3].

Exotherm control prevents 80°C+ heat cracks. Food-safe, low-VOC options suit dining tables in Wiltshire homes[4].

Viscosity and Flow for Seamless Rivers

Water-thin viscosity penetrates live edge cracks, ensuring bond strength. Thick epoxies trap bubbles, visible in lit rooms[1].

Pot Life and Working Time Essentials

Longer pot life suits big pours. CHILL’s 600 minutes beats short-life rivals[1].

UV and Yellowing Resistance

Bristol makers need UV blockers. Tested brands maintain clarity for decades[3].

Top 5 Epoxy Brands: What Brand of Epoxy is Best for a River Table Project?

Based on forums, tests, and my Bristol workshop trials, here are the leaders for what brand of epoxy is best for a river table project. CHILL, UltraClear, TotalBoat, EcoPoxy, and US Composites top the list[1][2][3][4].

1. CHILL Epoxy – Best overall for deep pours up to 3 inches[1].

2. UltraClear – Crystal clarity for UK pros[3].

3. TotalBoat – Beginner-friendly with strong UV protection[4].

4. EcoPoxy – Eco-friendly choice[2].

5. US Composites – Budget performer[2].

Comparative Strengths

| Brand | Max Depth | Pot Life | Price per L (approx £) |

|---|---|---|---|

| CHILL ICE 2 | 2″ | 600 min | £25-30 |

| UltraClear Deep Pour | 2″ | 450 min | £28-35 |

| TotalBoat Fathom | 3″ | 300 min | £20-25 |

| EcoPoxy | 1.5″ | 500 min | £30-40 |

| US Composites | 2″ | 400 min | £15-20 |

CHILL Epoxy: The Standout for Deep Pours in What Brand of Epoxy is Best for a River Table Project

CHILL tops answers to what brand of epoxy is best for a river table project with ICE 1 (1.5″ pours, 400 min pot life) and ICE 2 (2″, 600 min)[1]. TECHNO CAST handles 2-3″ masses perfectly.

Water-like flow suits 60L Bristol coffee tables. No blushing, excellent bubble release. I’ve used it for resin river dining tables in Bath homes, achieving glass-like finishes[1].

Pros: Long work time, low exotherm, UV stable. Cons: Higher cost at £25-30/L. Ideal for large Gloucestershire projects.

Real-World CHILL Performance

In my workshop, CHILL poured a 2.4m walnut river table without layers. Cured in 72 hours at 20°C, no heat issues[1].

UltraClear Epoxy: Ideal for UK River Table Makers Answering What Brand of Epoxy is Best for a River Table Project

UltraClear Deep Pour excels for what brand of epoxy is best for a river table project, filling 2″ gaps with crystal transparency[3]. Batch-tested in the USA for consistency.

Strong bonding embeds shells or LED lights seamlessly. Self-levels, resists scratches. Perfect for Bournemouth bar tops or Exeter consoles[3].

Pros: High gloss, easy maintenance, expert support. Cons: 1:1 mix ratio needs scales. £28-35/L value for pros.

Why UltraClear for South West Climates

Humidity-resistant, no yellowing in Plymouth sun. I’ve layered it for 1/4″ veins using Table Top formula[3].

TotalBoat Epoxy: Reliable Choice for What Brand of Epoxy is Best for a River Table Project

TotalBoat Fathom answers what brand of epoxy is best for a river table project for budgets, with 3″ pours and 100% waterproofing[4]. BPA-free, no VOCs.

Syrup viscosity controls flow on live edge slabs. Cures blush-free at room temp. Great for school projects or Swindon DIYers at £20-25/L[4][5].

Pros: Versatile kits (quart to 4 gallon), scratch/UV resistant. Cons: Shorter pot life for massive pours.

TotalBoat in Practice

Rockler-recommended, it suits carbon-infused tables. My trials show glassy finishes on oak rivers[4][5].

Other Strong Contenders for What Brand of Epoxy is Best for a River Table Project

EcoPoxy offers plant-based resin, popular on forums for low odour[2]. West System suits laminating but needs deep pour hardeners[2].

Alumilite from Woodcraft provides deep pour lines affordably[5]. US Composites 150 resin is budget king at £15/L, cloud-free indoors[2].

For what brand of epoxy is best for a river table project, these shine in niches like eco-focus or cost-saving.

Step-by-Step Guide to Using the Best Epoxy for Your River Table

1. Select wood: Kiln-dried walnut/maple, moisture under 8%.

2. Seal slabs: Thin epoxy coat, sand 220 grit.

3. Build dam: Melamine boards, taped seams.

4. Mix epoxy: 1:1 or 2:1 ratio precisely at 20-25°C.

5. Pour slowly: Torch bubbles, heat mat if needed.

6. Cure 72 hours, demould, sand to 400 grit, polish.

This process with top brands ensures success in Cornish workshops.

Tools Needed

- Digital scales

- Propane torch

- Heat gun

- Mixing drills

- Polishing pads

Common Mistakes and How to Avoid Them in River Table Projects

Bubbles from fast pours: Use low-viscosity like CHILL, pour thin streams[1]. Yellowing: Pick UV-stable brands[3]. Cracks: Limit mass, use fans.

Humidity woes in Dorset: Dehumidify to 50% RH. Wrong depth: Layer if over 2″. Always test small batches.

Expert Tips from a Bristol Carpenter on What Brand of Epoxy is Best for a River Table Project

Pre-warm resin to 25°C for flow. Add pigments post-mix. For live edge, fill knots first with thin resin.

In my Simmonds Carpentry projects, CHILL for big rivers, UltraClear for details. Source from UK suppliers to avoid import duties.

Food-safe certification vital for kitchen islands in Somerset. Polish with automotive compound for mirror shine.

Local South West Sourcing

Check Bristol tool shops or online for CHILL/TotalBoat. Budget £200-400 for a 2m table pour.

Cost Comparison for Epoxy Brands in the UK

Gallon kits: CHILL £100-120, UltraClear £110-130, TotalBoat £80-100. Factor waste: Buy 20% extra.

ROI high: A £500 river table sells for £2,000+ in Cheltenham markets. Cheaper brands risk reprints[2].

Conclusion: What Brand of Epoxy is Best for a River Table Project

Ultimately, what brand of epoxy is best for a river table project? CHILL Epoxy leads for deep, flawless pours, with UltraClear and TotalBoat close behind[1][3][4]. Match to your scale and budget.

As a Bristol specialist, I recommend testing samples. Your river table will captivate in any Wiltshire home. Start with CHILL for pro results. Understanding What Brand Of Epoxy Is Best For A River Table Project is key to success in this area.